Injection Molded Cup/Box With In-Mold Labeling Supplier

Injection-molded film labeling is a new packaging form that is different from traditional label packaging. The principle is to put the printed in-film labeling into the injection mold cavity, which improves the quality of the product, eliminates secondary printing, and improves the quality of the product. product safety and hygiene.

information to be updated

About Us

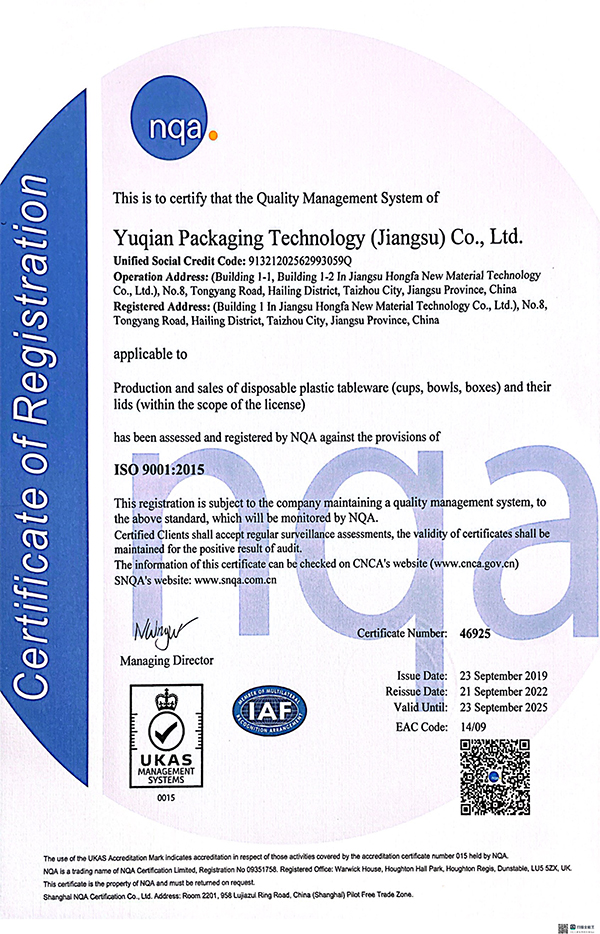

Yuqian Packaging Technology (Jiangsu) Co., Ltd. was established in 2010, located in Taizhou City, Jiangsu Province, plant area of 30000m, is a research and development, production and sales of new food packaging materials and products of high-tech enterprises. The division took the in the packaging industry to pass the QS national industrial product production license; IS09001 Quality Management system certification; BRC certification; German authoritative safety DIN certification; Eu ROHS+ testing and other certifications. Yuqian Packaging Technology (Jiangsu) Co., Ltd. was a professional OEM Injection molded cup with in-mold labeling Supplier and Injection molded box with in-mold labeling Company. Main biodegradable new materials and food packaging products, in order to improve service quality and expand business channels, the company set up a Shanghai branch in January 2019. Shanghai Yuqian Packaging Technology (Jiangsu) Co., Ltd.

Honor

-

ISO 9001

ISO 9001

News

-

Industry news 2026-01-22

In the fast-paced world of "coffee-to-go," the humble cup lid is often an afterthought—until it leaks on your white shirt or fails to keep your latte ...

View More -

Industry news 2026-01-15

In the fast-paced world of food service and beverage packaging, business owners and consumers alike are asking a critical question:Why do my plastic c...

View More -

Industry news 2026-01-08

In the fast-paced world of food service and takeaway beverages, business owners and consumers alike are asking the same question: Is there a single cu...

View More -

Industry news 2026-01-02

Troubleshooting Methods Even high-quality Peripheral Products may experience malfunctions due to external factors. Yuqian Packaging provides reliable ...

View More

Contact us now

Injection Molded Cup/Box With In-Mold Labeling Industry knowledge

Injection Molded Box With In-Mold Labeling is an innovative packaging form introduced by our company. It embeds the printed in-film label directly into the injection mold cavity and integrates it with the product during the injection molding process. This packaging method not only improves the overall aesthetics of the product, but also significantly improves the quality and safety of the product.

The working principle of in-mold labeling technology is relatively simple and efficient. First, the printed in-film label is accurately placed in the cavity of the injection mold. Then, during the injection molding process, the molten plastic fills the mold and tightly wraps the in-film label. As the plastic cools and solidifies, the in-film label and injection molded box become an integral whole.

As a high-tech enterprise, we have a strong R&D team and advanced production equipment, able to provide customers with customized injection boxes and in-mold labeling solutions to meet the needs of different industries and products. Our main business is biodegradable new materials. The injection boxes and in-mold labels we produce are all made of environmentally friendly materials, which comply with international environmental standards, reducing environmental pollution and improving product sustainability.

In-mold labeling technology eliminates the secondary printing and pasting process of traditional labels, reduces errors and contamination in the production process, and thereby improves the overall quality of the product. Since the in-film labeling and the injection box are closely combined during the molding process, the label is not easy to fall off or be damaged, effectively preventing the label from being maliciously replaced or tampered with, thereby ensuring product safety and hygiene. Although the initial investment in equipment and molds for in-mold labeling may be high, because we have large-scale factories and advanced production lines, we can achieve large-scale production, thereby reducing costs and improving production efficiency.

Injection Molded Box With In-Mold Labeling technology are widely used in the packaging fields of food, medical, electronics, daily chemical and other industries. Especially for products with higher packaging requirements, such as high-end food, medical equipment, electronic products, etc., in-mold labeling technology has become the preferred packaging method.

When selecting in-film labeling materials, you should ensure that they have good compatibility with the injection molding material to avoid chemical reactions or delamination during the injection molding process. Our company provides professional material selection and testing services to ensure customers get the best product results. The printing quality of in-film labeling has an important impact on the appearance and quality of the final product. Our company has advanced printing equipment and rich printing experience, able to provide customers with high-quality printing services. During the injection molding process, parameters such as mold temperature and injection pressure should be strictly controlled to ensure that the in-film labeling is closely integrated with the injection box and achieves the desired appearance. Our company provides comprehensive technical support and after-sales service to ensure that customers obtain the best product quality and production efficiency during the production process.

English

English Español

Español عربى

عربى